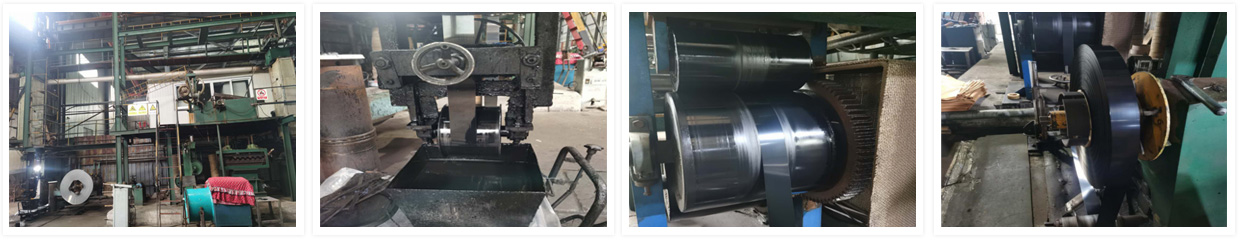

Cold rolled: hot rolled steel as raw material has been processed through pickling to remove the oxide scale then cold rolling. The production of cold rolled steel strips include the picking, cold rolling, degeasing, annealing, leveling, finishing, polishing, etc, It not only achieves to the highest production efficiency and the most perfect automation control in the steel field by the production department, but also representing the outstanding and greatest level of steel rolling technology.

Our cold-rolled steel coils must be under further processes after annealing, including cutting head & tail, trimming, straightening, leveling, recoiling or slitting.etc

| Material | Size(mm) | Hardness | Application | Remark | Color | ||||||

| CK50 | 0.26*68;0.3*70 0.325*80;0.4*80 |

820-840HV | Car horn,The buzzer inside a motorcycle horn.etc | Low-end car | According to the customer’s requirement | ||||||

| CK67/C70 | Mid-range car | ||||||||||

| 51CrV4 | Premium car |

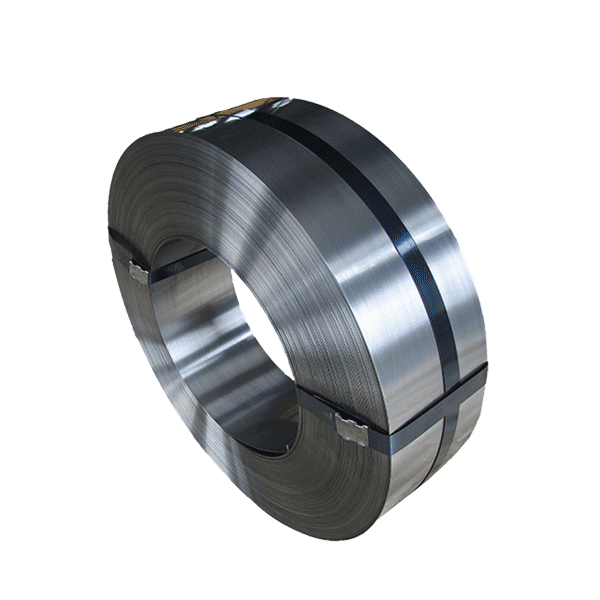

Products are widely applied in hardware tools, all kinds of clay tile, putty knife, bricklaying knife, float, shovels, woodworking band saw, saw blade, all kinds of garden saw, hand saw, saw blades, automotive clutch plate, gate rounded edge spring steel band, clock spring, lock, shoes materials, textile, sickle, standard stamping materials, there are all kinds of color packing belt, steel belt and other industries use.

Cgoodsteel`s hardening and tempering process involves heating the steel strip to a critical transition temperature above a given level and then rapidly cooling it. The steel strip in this case is very brittle and is then heated to the lowest temperature and maintained at a given temperature for a given period of time. This process is to avoid oxidation in an inert atmosphere.

High corrosion resistance, low noise, high elasticity, non-deformation of spring steel sheet arc, matches perfectly with wind screens of different arcs, more uniform, wiping effect excellent, and adapting to the climate in different regions of the world.

At present, the main types of annealed steel strips we produce are: full hydrogen annealing steel strip, spheroidizing annealing steel strip, general annealing steel strip

Hot rolled steel as raw material has been processed through pickling to remove the oxide scale then cold rolling. The production of cold rolled steel strips include the picking, cold rolling, degeasing, annealing, leveling, finishing, polishing, etc, It not only achieves to the highest production efficiency and the most perfect automation control in the steel field by the production department, but also representing the outstanding and greatest level of steel rolling technology. Our cold-rolled steel coils must be under further processes after annealing, including cutting head & tail, trimming, straightening, leveling, recoiling or slitting.etc